Why do we need metallized ceramics ?

Ceramics is inorganic non-metallic materials. It has the properties of high temperature resistance, wear resistance, strong corrosion resistance, low density, good insulation performance, poor plasticity, high brittleness, difficult processing.

Meta is metallic materials. It has the properties of low temperature resistance, fast wear, poor corrosion resistance, electrical conductivity, good plasticity, and easy processing.

In some specific fields, it is necessary to combine the advantages of both materials.

Can ceramic and metal can be bonded directly?

When brazing ceramics and metals, there is an essential difference between the atomic structure of ceramic materials and metals. Therefore, there are many problems in the brazing of ceramics and metals. Due to the poor wettability of ordinary metal brazing materials and ceramic surfaces. Therefore, improving the wettability of the solder re-ceramic surface is an important factor to ensure the quality of brazing.

In order to realize the brazing of ceramic and metal, to coated a metal layer into ceramic surface is necessary.

To coating a metal layer into ceramics is called ceramic metallization

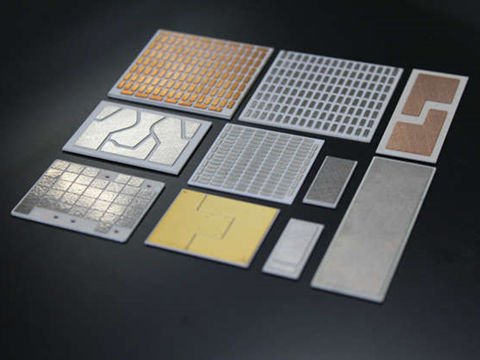

Most common methods are :

- Thick-Film Ceramic Metallization.

- Direct Bonded Copper (DBC)

- Thin-Film Ceramic Metallization

Commonly materials using for ceramic metallization:

- 1. 96% Alumina Ceramics (96% Al2O3)

- 2. Aluminum Nitride Ceramics (ALN)

- 3. Beryllium Oxide Ceramics (BEO)

Compared Material Properties

| Item No. | Properties | Unit | Value | ||

| 96% Al2O3 | ALN | 97% BeO | |||

| 1 | Dielectric Constant | 1MHz、(10±0.5) GHz | 9-10 | 9 | 6.9 |

| 2 | Dielectric Loss Factor | 1MHz | 2.0*10-4 | 3.8*10-4 | ≤ 4×10-4 |

| 3 | Volume Resistivity | Ω·cm (25 C) | ≥ 1015 | ≥1013 | ≥ 1014 |

| 4 | Dielectric Strength | KV/mm | ≥ 30 | ≥ 17 | ≥ 15 |

| 5 | Flexural Strength | MPa | ≥ 300 | ≥ 300 | ≥ 170 |

| 6 | Bulk Density | g/cm3 | ≥ 3.65 | ≥ 3.30 | ≥ 2.85 |

| 7 | Average Coefficient of Linear Expansion | 1/K(25~500 C) | (6.5~7.5)x10-6 | (4.6)x10-6 | (7.0~8.5)x10-6 |

| 8 | Thermal Conductivity | W/(m·K) (25C) | ≥24 | ≥170 | ≥200 |

How to use metallized ceramics ?

Brazing metallized ceramics with metal as request.

Where do we use metallized ceramics ?

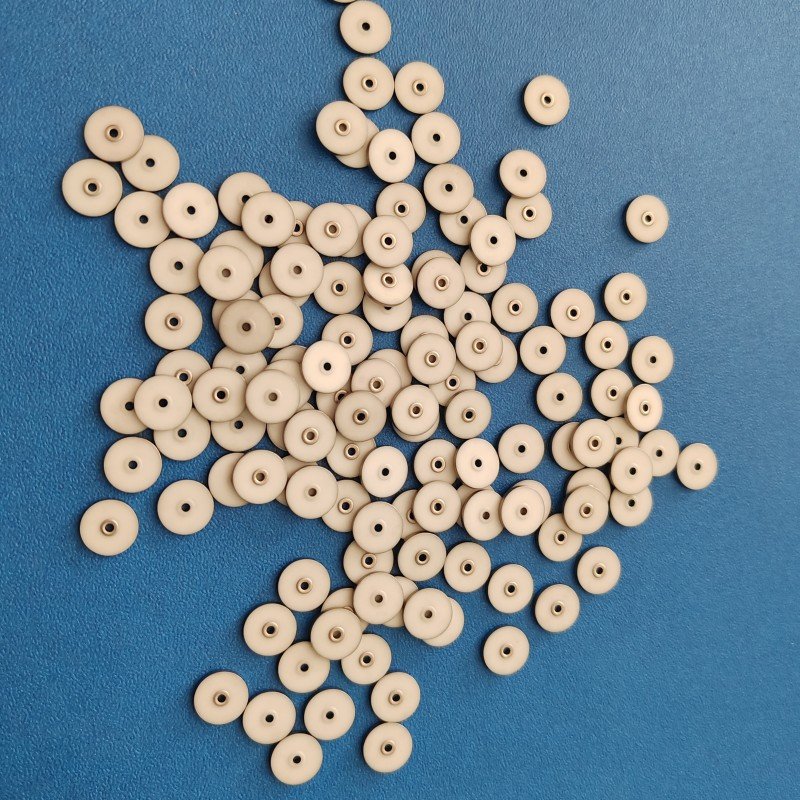

- Vacuum Interrupter Ceramic Tube

- High Voltage-resistance Alumina Ceramic

- Feedthroughs

- Beam Positioning Monitors

- Isolator Flanges

- High Vacuum, High Voltage, High Pressure applications.