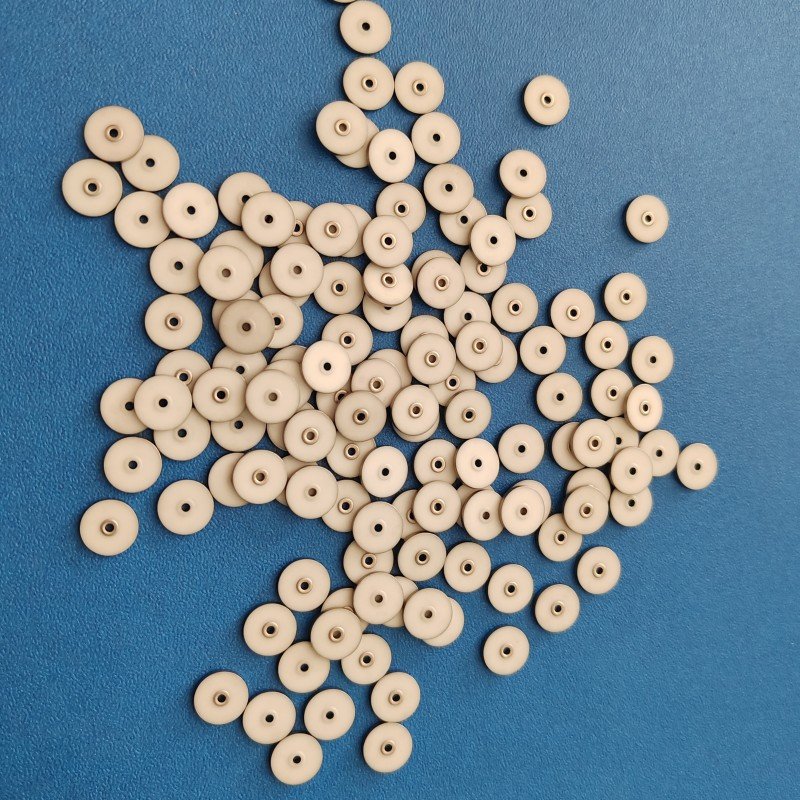

Metallization of alumina ceramics is a technical method of obtaining metalization treatment on the surface of alumina ceramics.

Through metalization treatment, alumina ceramics can be endowed with better conductivity, thermal conductivity, and mechanical properties, thereby expanding their application fields and functions.

1.What is aluminum oxide ceramic metallization?

Metallization of alumina ceramics refers to the formation of a layer of metal slurry coating on the surface of alumina ceramics, which endows the performance characteristics of alumina ceramics with metal through the combination of metal and ceramics.

The metallized material can be Mo/Mn, W, Au, Ti etcs.

Metallization treatment can improve the conductivity, thermal conductivity, and mechanical properties of alumina ceramics, making them more durable and suitable for various application scenarios.

The commonly used methods for metallization of alumina ceramics include chemical plating, electroplating, and vapor deposition.

Chemical plating is the process of reducing and depositing metal ions onto the surface of ceramics to form a metal coating. Electroplating uses electrolytic current to deposit metal cations onto the surface of ceramics, while vapor plating evaporates the metal material and deposits it onto the surface of ceramics.

Application of Alumina Ceramic Metallization Alumina ceramic metallization has superior performance and can be widely used in various fields.

Firstly, metallized alumina ceramics are widely used in the electronics industry as shells and heat sinks for electronic components, exhibiting excellent conductivity and thermal conductivity.

Secondly, metallization also makes aluminum oxide ceramics suitable for the chemical industry, as corrosion-resistant equipment to improve their service life.

In addition, metalization treatment can also change the surface color and texture of alumina ceramics for decoration and aesthetic design.

The advantages of alumina ceramic metallization include the following.

Firstly, metalization treatment can improve the conductivity of alumina ceramics, giving them excellent conductivity.

Secondly, metalization can also improve the thermal conductivity of alumina ceramics, enabling them to dissipate heat better and increase their stability in high-temperature environments.

In addition, metalization treatment can also increase the mechanical strength and hardness of alumina ceramics, improve their wear resistance and corrosion resistance.

Metallization of alumina ceramics is a technical method of obtaining metalization treatment on the surface of alumina ceramics.

Metallization treatment can improve the conductivity, thermal conductivity, and mechanical properties of alumina ceramics, expand their application fields, and make them suitable for multiple fields such as electronics and chemical industries.

Metallization treatment enables alumina ceramics to have excellent performance and can be used for decoration and aesthetic design.

The advantages of aluminum oxide ceramic metallization lie in improving conductivity, thermal conductivity, and mechanical properties, as well as increasing its stability and durability.