Heateron’s metallized ceramics are using in ceramic feedthroughs. The ceramic feedthroughs are ceramic-to-metal assemblies used to transmit signals, high voltages, high currents, gases or fluids from outside a hermetically-sealed chamber to the inside.

These ceramic feed-throughs are designed to provide electrical insulation and high mechanical strength. They are hermetic and maintain ultra-high levels of vacuum and joint integrity that are maintained at elevated temperatures, cryogenic conditions and in harsh environments. Feedthroughs can be classified in 3 groups:

- Feedthroughs for low voltages (up to 12 kV) typically convey a signal

- High-voltage feed-throughs (20 to 100 kV)

- Water-cooled feed-throughs and RF feed-throughs typically used in CO2 lasers

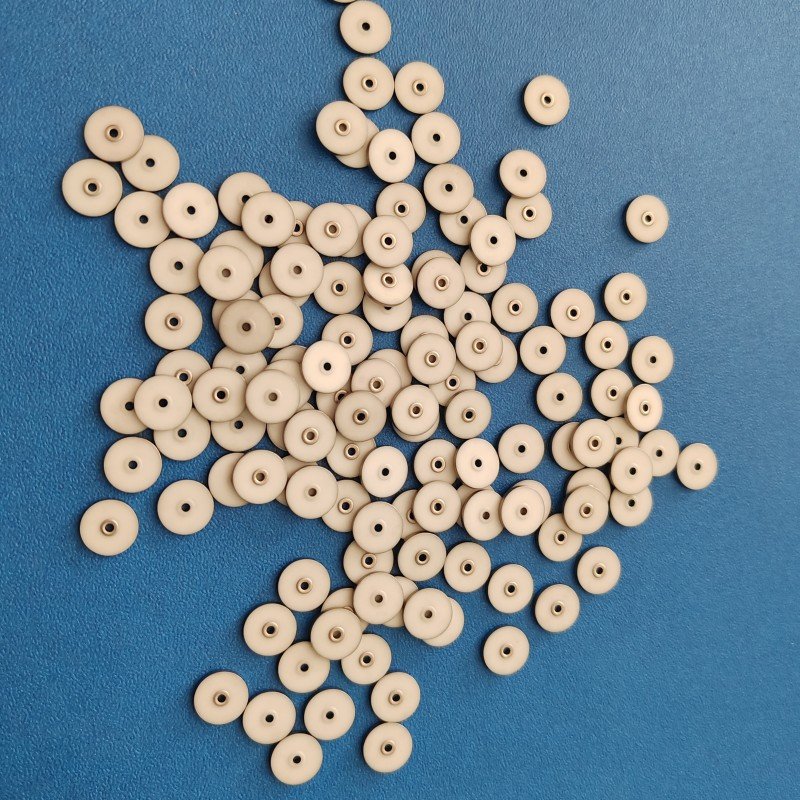

The metallized ceramics is using high purity alumina ceramics. And thick film metallized with Mo/Mn layer.

Ceramic Dimension is from OD1.0mm to OD200mm.

Mo/Mn layer thickness from 10-50um.

Ni plating layer is from 2-10um.

Heateron have ability to provide all ceramic metallization solutions for all kind of feedthroughs.

From more informations , just email us.