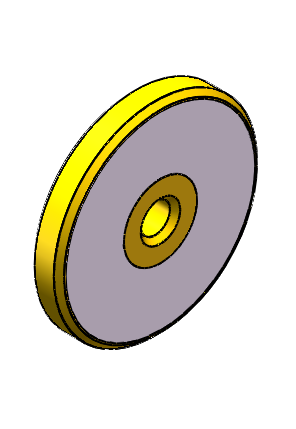

Metallized Ceramic substrate is a special process which copper directly bonded to the ceramic substrate surface at high temperature. The metallized ceramic substrate has the properties of excellent electrical insulation, high thermal conductivity, excellent solderability and high adhesion strength. It can be etched with various patterns like PCB boards.

Major features:

High strength

High thermal conductivity

High insulation

Anti-corrosion

Good thermal cycle performance

The operation temperature range is -55℃~850℃. The thermal expansion coefficient is close to silicon.

Ceramic Substrate material :

Aluminium Oxide (Al2O3)

Beryllium Oxide (BeO)

Aluminium Nitride (ALN)

Prodution Types:

HTCC (High-temperature Co-fired Ceramic)

LTCC (Low-Temperature Co-fired Ceramic)

DBC (Direct Bonded Copper)

DPC (Direct Plated Copper)

Applications:

High-power semiconductor modules

Semiconductor refrigerators

Electronic heaters

Power control circuits

Power hybrid circuits

Intelligent power components

High-frequency switching power

Relays

Automotive Electronics

Etcs