As a non-metallic material, ceramics have excellent physical and chemical properties and therefore are widely used in the semiconductor industry. We will introduce the application fields and specific application cases of ceramics in the semiconductor industry, as well as the advantages and challenges of ceramics.

Where can we found ceramic in semiconductor manufacturing?

1.Electronics packaging

Ceramics are widely used in the housing and substrate of semiconductor devices in the field of electronic packaging. The ceramic shell provides good mechanical protection and thermal conductivity, protecting the device from interference from the external environment. Ceramic substrates are used to connect and support electronic components. Their excellent insulation properties and thermal stability enable electronic components to operate stably in harsh working environments.

2.Circuit Board

Ceramic circuit boards are widely used in high-frequency electronic equipment, such as wireless communication equipment and radar systems. Ceramic circuit boards have low dielectric loss and excellent thermal properties, providing better signal transmission and higher operating frequencies. In addition, ceramic circuit boards also have good dimensional stability and mechanical strength, and can meet the wiring requirements of complex circuits.

3.Heat Sink

The application of ceramics in heat sinks mainly utilizes their excellent thermal conductivity properties. Since semiconductor devices generate a large amount of heat during operation, it needs to be dissipated through a heat sink to ensure the normal operation of the device. Ceramic materials have high thermal conductivity and excellent thermal stability, which can effectively conduct heat to the surface of the radiator and improve heat dissipation efficiency.

Which ceramic parts can we found in Semiconductor Industry ?

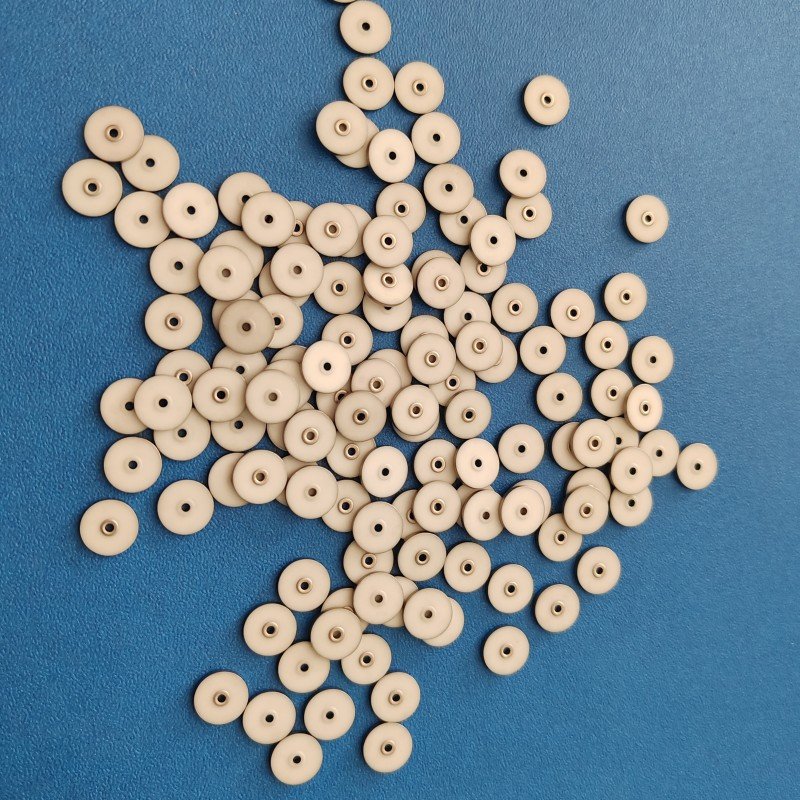

1.Alumina Ceramic Package

Alumina ceramic packages are widely used in high-frequency electronic equipment. It has excellent mechanical strength, good insulation properties and high thermal conductivity, which can effectively protect electronic components and provide good signal transmission and heat dissipation properties.

2.Alumina ceramic substrate

Alumina ceramic substrates are widely used for connection and support of electronic components. It has excellent insulation properties and thermal stability, and can operate stably in high temperature and high voltage environments. In addition, alumina ceramic substrates also have good dimensional stability and mechanical strength, and can meet the wiring requirements of complex circuits.

3.Silicon nitride ceramic circuit board

Silicon nitride ceramic circuit boards are widely used in high-frequency electronic equipment. It has low dielectric loss, excellent thermal performance and higher operating frequency, and can provide better signal transmission and higher operating frequency. In addition, silicon nitride ceramic circuit boards also have good dimensional stability and mechanical strength, and can meet the wiring requirements of complex circuits.

Conclusion

Ceramics have a wide range of applications in the semiconductor industry, including electronic packaging, circuit boards, and thermal heat sinks. Ceramic materials have excellent physical and chemical properties and can meet the material performance requirements of the semiconductor industry. However, there are some challenges in the manufacturing and processing of ceramic materials that require further research and improvement. With the continuous development of semiconductor technology, the application prospects of ceramic materials in the semiconductor industry will be broader.