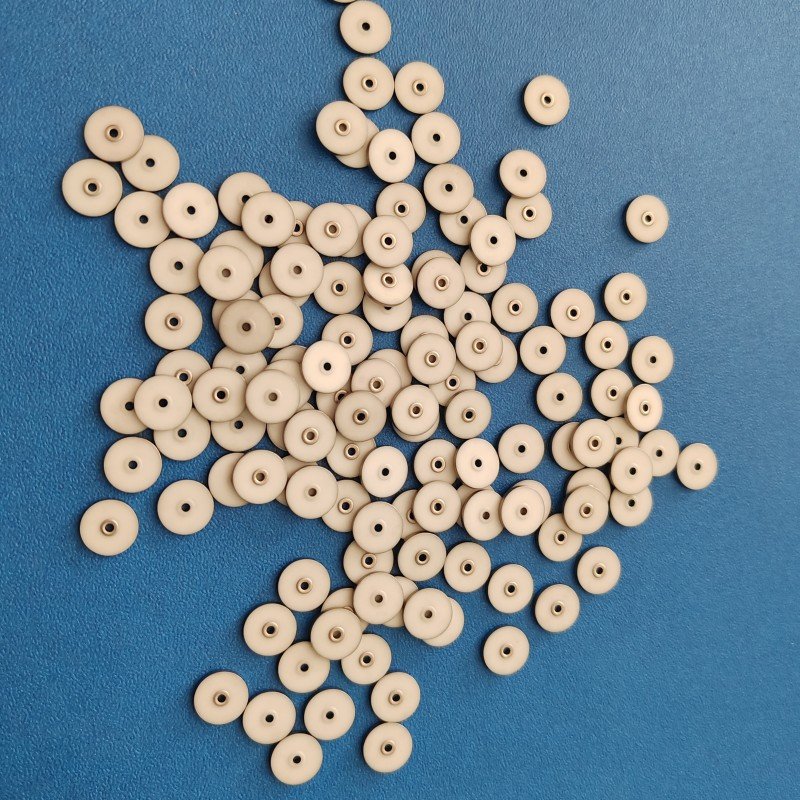

Heateron Ceramic Laser Cavity is using 99% Al2O3 and fired at an appropriate temperature to retain the appropriate porosity and strength of the body. The surface of the reflector adopts a fully coated high reflectivity ceramic glaze process, which has a major advantage over gold-plated reflectors due to its extremely long service life and diffuse reflection characteristics. At present, our company produces various types of lamp pumped ceramic cavities, including laser welding machines, laser cutting machines, laser marking, and medical industries. Ceramic cavities can also be customized according to your needs.

Major features:

1. Full glazed surface for high reflectivity and easy cleaning

2. Reflectivity reaches 98% at wavelengths of 600-1000nm

3. Reflectivity exceeding 96% in the spectral range of 400-1200nm

4. The green body has appropriate porous and high-strength characteristics

Physical property:

Color: White

Density: 3.1g/cm3

Porosity:22%

Bending strength: 170Mpa

Thermal expansion coefficient:

7.9×10-6–/С(200~500℃)

9×10-6/С(200~1000℃)

Major applications:

1.Industrial lasers

2.Medical lasers

3.Intense pulse lamp

4.DPSS lasers

There are many standard and custom laser cavitys are available.